Lumen tube production process stability

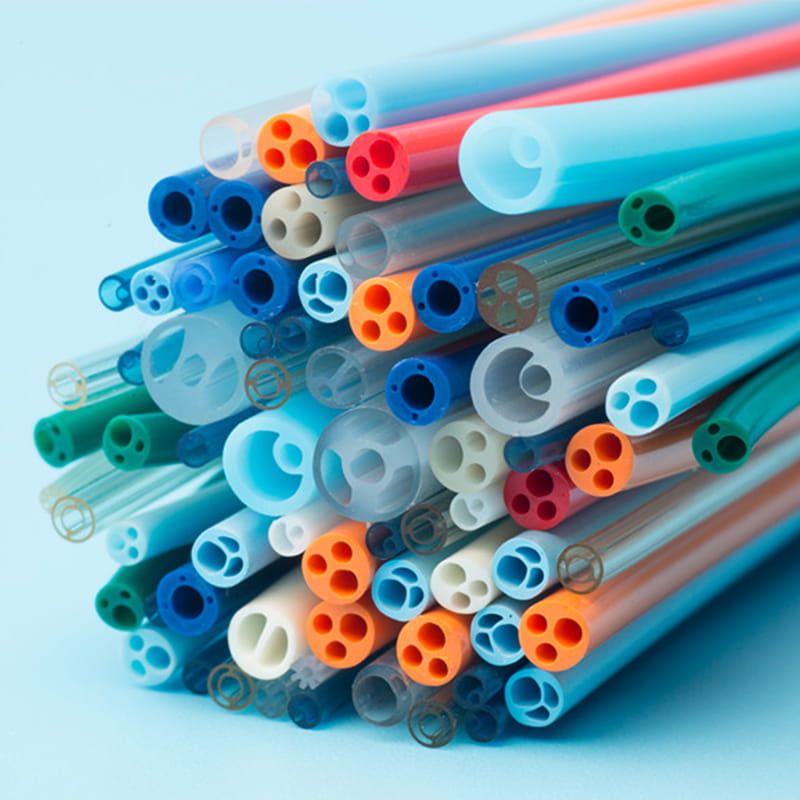

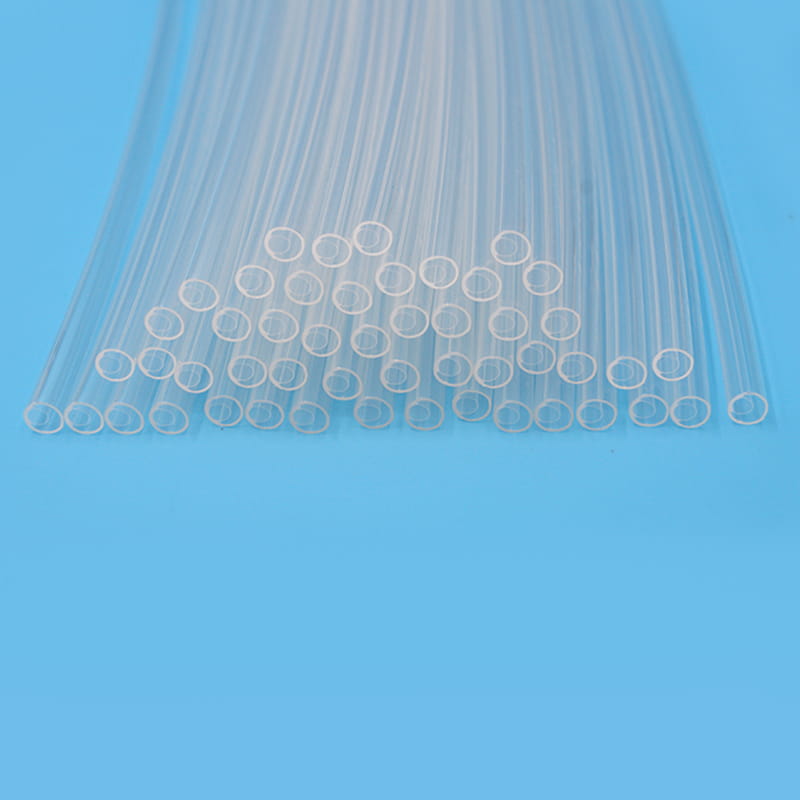

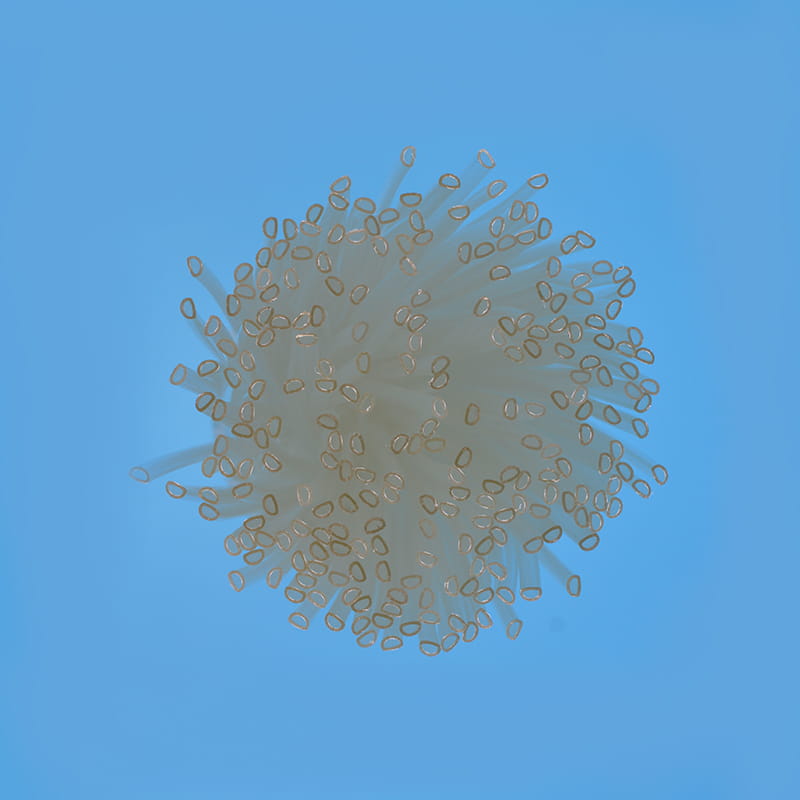

In the intricate world of medical device manufacturing, multi-lumen tubing stands as a testament to technological advancement and precision engineering. These specialized tubes, featuring multiple parallel channels within a single structure, are indispensable in various medical applications, including drug delivery systems, catheters, and dialysis equipment. Ensuring the stability of the multi-lumen tubing production process is paramount to maintaining product quality, safety, and regulatory compliance. This article delves into the key factors that contribute to achieving production stability in this highly specialized field.

1. Material Selection and Quality Control

The foundation of any stable production process lies in the quality of raw materials. For multi-lumen tubing, selecting high-grade polymers that exhibit excellent chemical resistance, biocompatibility, and dimensional stability is crucial. Implementing rigorous quality control measures at the material sourcing stage ensures that only the best-suited materials enter the production line. This includes verifying material certificates, conducting in-house testing for physical and chemical properties, and maintaining traceability throughout the supply chain.

2. Advanced Extrusion Technology

The extrusion process, where the polymer is melted and forced through a die to form the tubing, is the heart of multi-lumen tubing production. To achieve stability, manufacturers rely on advanced extrusion equipment capable of precise temperature control, pressure regulation, and die design. Multi-layer and co-extrusion technologies enable the simultaneous extrusion of different materials or layers, ensuring precise alignment and bonding of the lumens. Regular maintenance and calibration of extrusion machines are essential to maintain process consistency and prevent defects.

3. Process Optimization and Automation

Optimizing the production process through automation and continuous improvement initiatives is key to ensuring stability. Automated systems reduce human error, enhance repeatability, and allow for real-time monitoring and adjustment of critical process parameters. By leveraging data analytics and machine learning algorithms, manufacturers can identify trends, anticipate issues, and make data-driven decisions to fine-tune the process. Additionally, implementing Six Sigma or Lean Manufacturing methodologies can help streamline workflows, eliminate waste, and improve overall process efficiency.

4. Environmental Control

Maintaining a stable and controlled production environment is vital for multi-lumen tubing production. Factors such as temperature, humidity, and cleanliness can significantly impact the quality of the final product. Implementing strict environmental control measures, including temperature-controlled rooms, humidity regulation, and rigorous cleanliness protocols, ensures that the production environment remains optimal throughout the process.

For more information, please call us at +86-18913710126 or email us at [email protected].

From September 24 to 26, 2025, Anjun Medical Technologies (Suzhou) Co., Ltd. successfully participat...

Suzhou, China – April 9, 2025 – Anjun Medical Technologies (Suzhou) Co., Ltd., a leading provider of...

Recently, Anjun Medical Technologies (Suzhou) Co., Ltd. participated in the Dubai Medical Device Exh...

Arab Health 2025.01.27-30ANJUN. Z4.F30-C

Recently, Anjun Medical Technologies (Suzhou) Co., Ltd. was honored to participate in the internatio...