Crafting Precision: How Do We Ensure Perfect Bends in Medical Catheters?

In the vast starry sky of medical technology, medical catheters are the filaments that connect life and hope. Their design and manufacturing not only carry technological innovation, but also contain endless respect and care for life. Especially in the subtle and critical field of catheter bending, every detail embodies the wisdom and sweat of engineers. They are ingenious and strive to accurately outline the trajectory of life exploration in every bend.

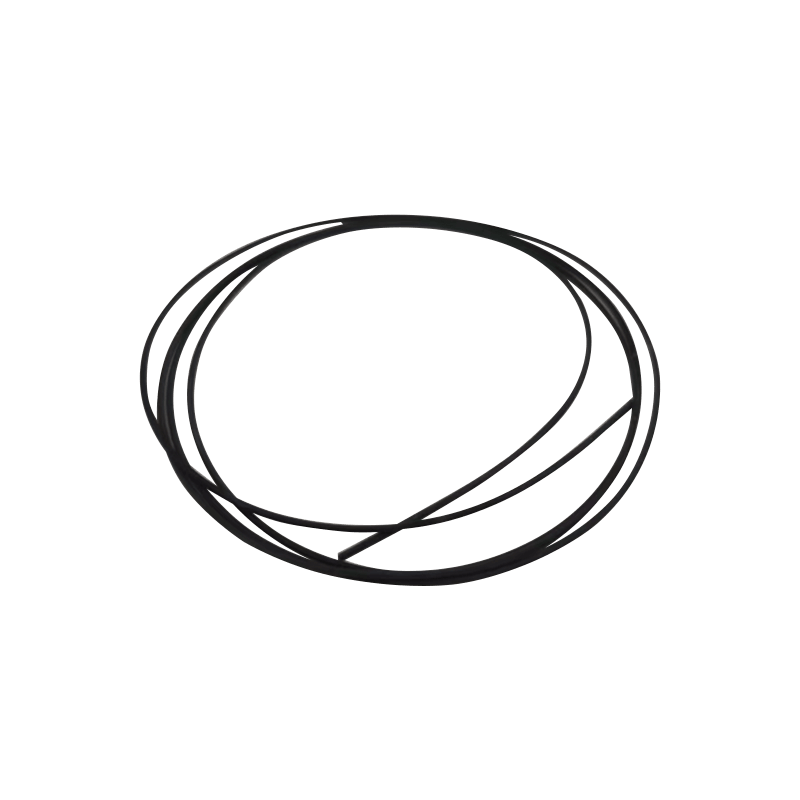

The bending process of medical catheter curving with the careful selection and careful adjustment of the mandrel. As the core support in the bending process, the choice of material, size and shape of the mandrel directly determines the accuracy and stability of the catheter bending. Engineers carefully select high-strength and high-wear-resistant mandrel materials according to the specific use, size requirements and expected bending shape of the catheter, and through precise mechanical adjustment, ensure the perfect fit between the mandrel and the catheter, laying a solid foundation for subsequent bending operations.

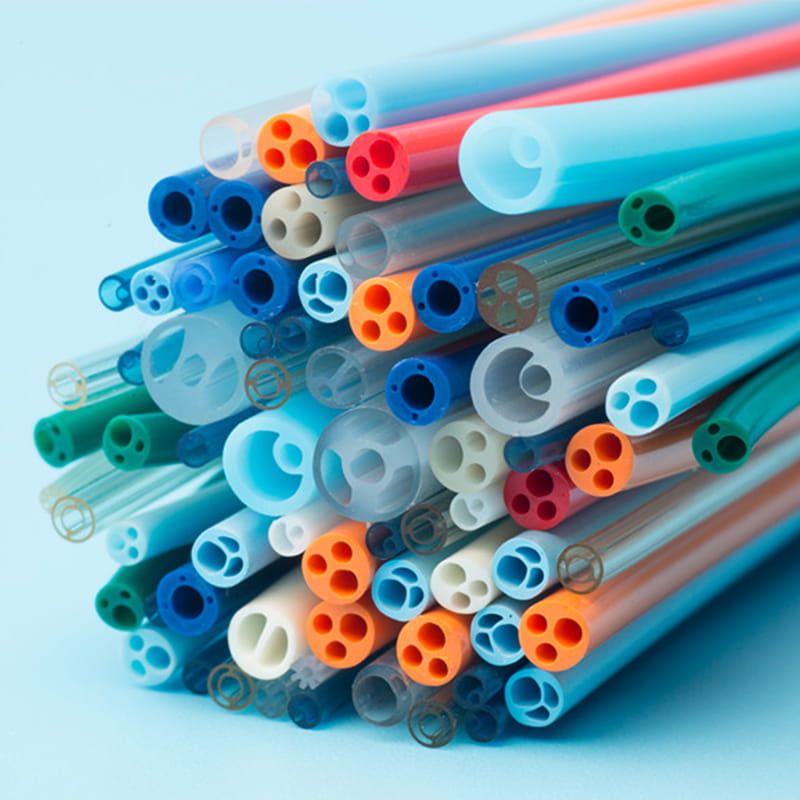

As the "mold master" of medical catheter curving and forming, the mold's precision control is the top priority in the processing process. Modern medical-grade molds use advanced CNC processing technology, combined with high-precision measuring equipment, to strictly control every detail of the mold to ensure that the mold surface finish, dimensional accuracy and shape consistency meet the highest industry standards. It is this extreme pursuit of mold accuracy that enables medical catheters to present a perfect shape during the bending process and meet complex and changing medical needs.

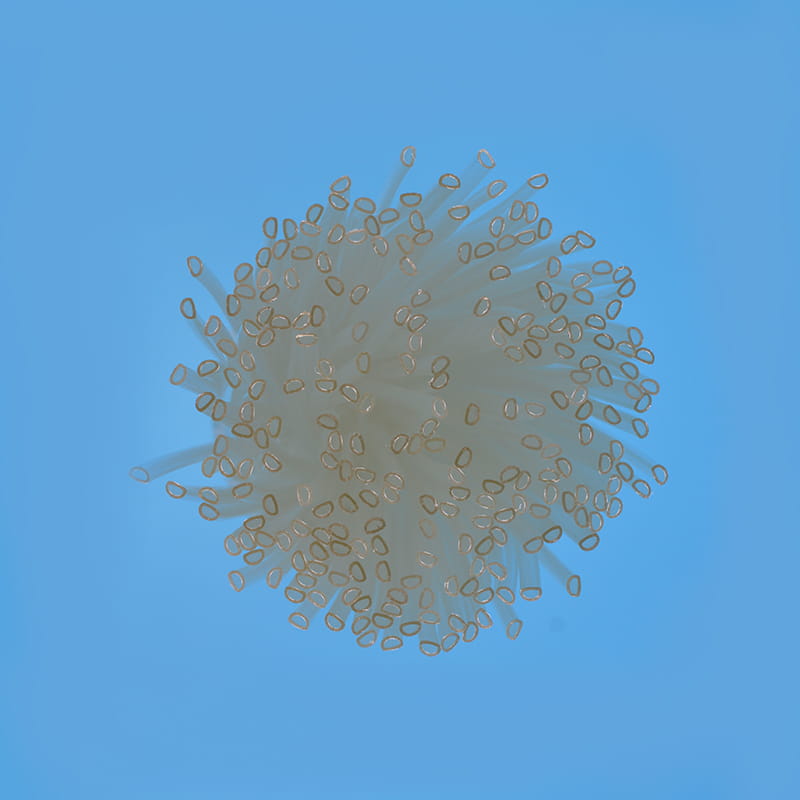

The shaping of the catheter tip is the pinnacle of technology in the bending process of medical catheters. It requires that the catheter tip must have sufficient flexibility to conform to the complex and changing anatomical structure of the human body, and maintain sufficient stability to ensure accurate navigation during surgery without deviating from the established path. In order to achieve this goal, engineers continue to innovate processing technology, using advanced heat treatment processes, micro-machining technology and precise bending control algorithms to finely carve the catheter tip, so that it can maintain flexibility while also showing excellent shape retention ability, providing doctors with reliable surgical navigation tools.

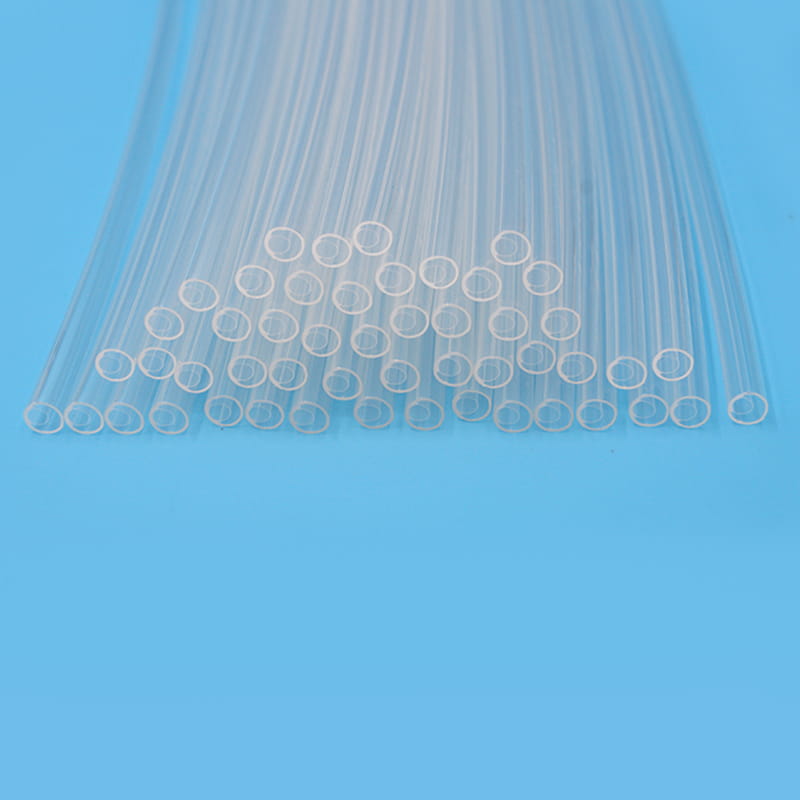

Throughout the entire process of medical catheter curving, quality control is always carried out throughout every link. From strict screening of raw materials, to real-time monitoring of the production process, to comprehensive testing of finished products, every step follows the most stringent quality standards. By introducing advanced testing equipment and quality management systems, we ensure that each medical catheter can achieve the best bending performance, biocompatibility and service life, providing solid protection for the patient's life safety.

The bending process of medical catheters is a great cause that combines technology, art and responsibility. It not only reflects the engineers' ultimate pursuit of technology, but also demonstrates the deep concern of medical technology for life and health. In the future development, we have reason to believe that with the continuous advancement of technology and continuous innovation of technology, the bending process of medical catheters will reach a more outstanding level and contribute more to the medical industry.

For more information, please call us at +86-18913710126 or email us at [email protected].

In the medical field, the safety, stability, and efficiency of fluid transmission are directly relat...

Introduction In modern medical procedures, particularly those involving minimally invasive surgery o...

Vascular interventional procedures are integral to modern cardiovascular medicine, particularly when...

Introduction Single-lumen endobronchial tubes are a critical component of respiratory therapy, espec...

The medical industry is increasingly relying on advanced materials for various applications, and one...

A medical balloon catheter is a sophisticated medical device designed to perform a variety of proced...