How does Medical Precision Catheter ensure that the selected materials have good biocompatibility?

When designing and manufacturing a Medical Precision Catheter, how do you ensure that the selected material is not only biocompatible but also able to meet the mechanical properties required of the catheter (such as softness and elasticity)?

When designing and manufacturing a Medical Precision Catheter, ensuring that the selected material not only has good biocompatibility but also meets the mechanical properties required of the catheter, such as softness and elasticity, is a complex and critical process. Here are some suggested steps and approaches:

material selection:

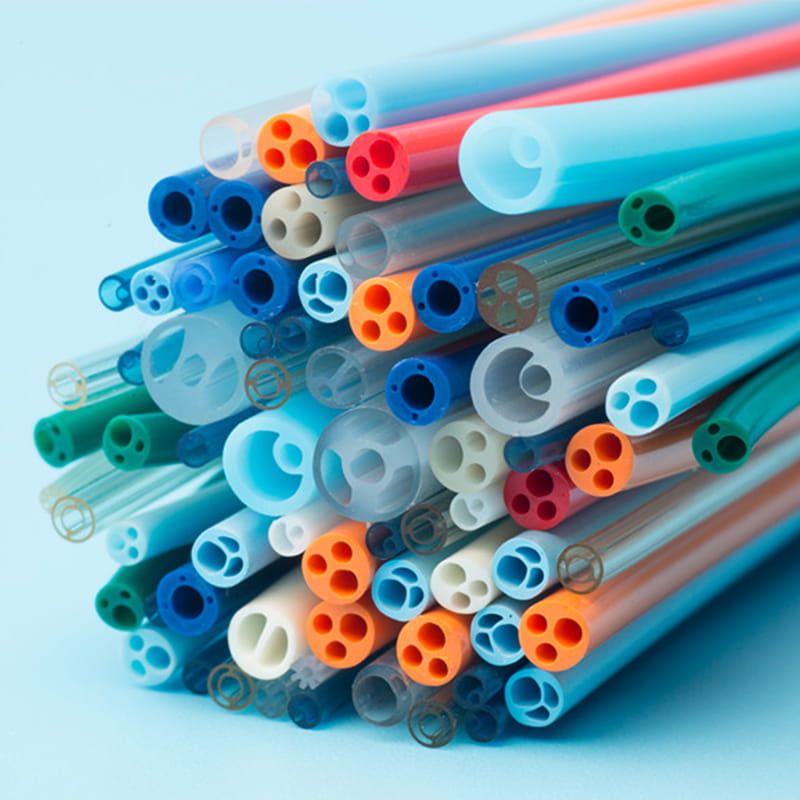

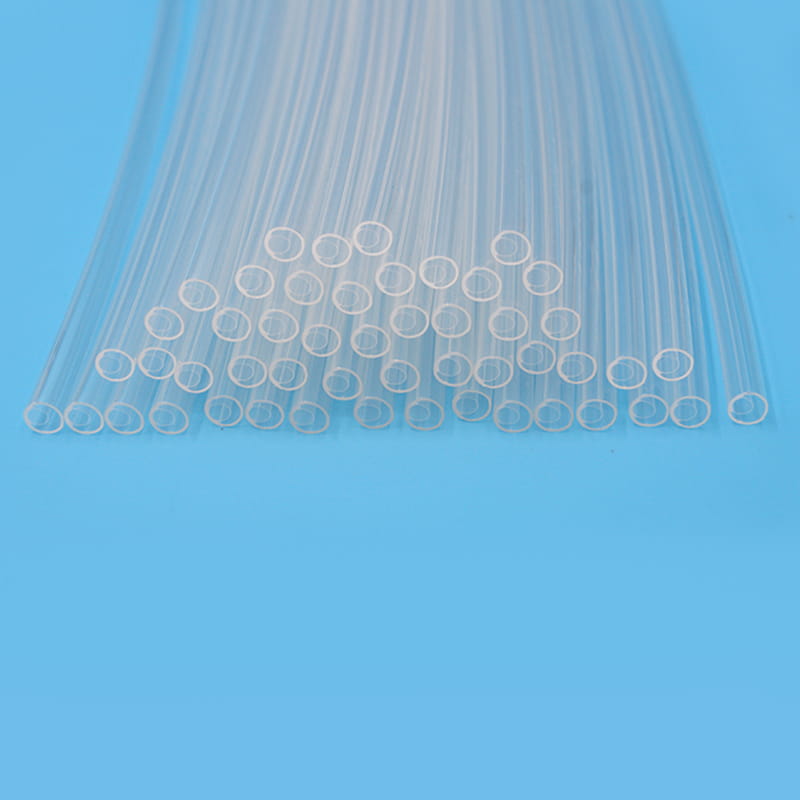

Choose biocompatible materials such as silicone rubber, polyurethane (PU), polytetrafluoroethylene (PTFE), etc. These materials have been widely demonstrated to have good biocompatibility in medical applications.

Evaluate the mechanical properties of materials, including hardness, elasticity, flexibility, etc. This information can be obtained by consulting data sheets provided by the material supplier, performing laboratory testing, or consulting with a materials science expert.

Choose a material that meets the required mechanical properties of the conduit. Depending on the catheter's intended use (e.g., cardiac catheter, angiography catheter, etc.), determine the desired range of stiffness, elasticity, and flexibility.

Material testing:

After the materials are selected, biocompatibility testing is performed, such as cytotoxicity testing, allergen testing, skin irritation and sensitivity testing, etc. These tests evaluate the safety and stability of materials in the human environment.

At the same time, mechanical performance tests are performed, such as hardness test, tensile test, bending test, etc. These tests evaluate the softness, elasticity and durability of materials.

Material optimization:

If the biocompatibility or mechanical properties of the selected material do not meet requirements, material optimization can be considered. For example, improving the biocompatibility or mechanical properties of materials by changing their formulation, adding modifiers, or performing surface treatments.

You can also consider using composite materials or multi-layer structures to combine the advantages of different materials to meet the overall performance requirements of the catheter.

Manufacturing process control:

During the manufacturing process, manufacturing process parameters are strictly controlled to ensure stable performance of the catheter. For example, parameters such as heating temperature, cooling rate, and stretch ratio can be controlled to obtain the required hardness and elasticity of the conduit.

Use advanced manufacturing technology and equipment, such as precision molds, laser cutting, etc., to ensure the dimensional accuracy and shape stability of the catheter.

Quality control and testing:

Establish a strict quality control and testing system to conduct biocompatibility and mechanical performance tests on each batch of catheters. This ensures product consistency and reliability.

For unqualified products, conduct cause analysis and take corrective measures to avoid similar problems from happening again.

keep improve:

Continue to pay attention to the latest advances in medical technology and changes in market demand, and continuously improve and optimize the design and material selection of catheters.

Maintain close cooperation with material suppliers and scientific research institutions to jointly develop new materials and manufacturing processes to meet higher performance requirements.

When designing and manufacturing Medical Precision Catheter, the biocompatibility and mechanical properties of the material need to be comprehensively considered, and the quality and performance of the product must be ensured through rigorous testing and optimization.

For more information, please call us at +86-18913710126 or email us at [email protected].

Introduction The TPU Reducer Tube (Thermoplastic Polyurethane Reducer Tube) is a versatile and high-...

In modern medicine, medical catheters are indispensable tools used in a wide range of treatments and...

In the healthcare industry, the importance of selecting the right materials for medical devices cann...

In the era of precision medicine, a small tube often carries the weight of life-saving responsibilit...

In modern healthcare, precise fluid management is crucial for patient safety and treatment efficacy....

Introduction The field of minimally invasive medical procedures has witnessed remarkable growth over...