Material Selection for Medical Precision Catheters: Ensuring Biocompatibility and Stability

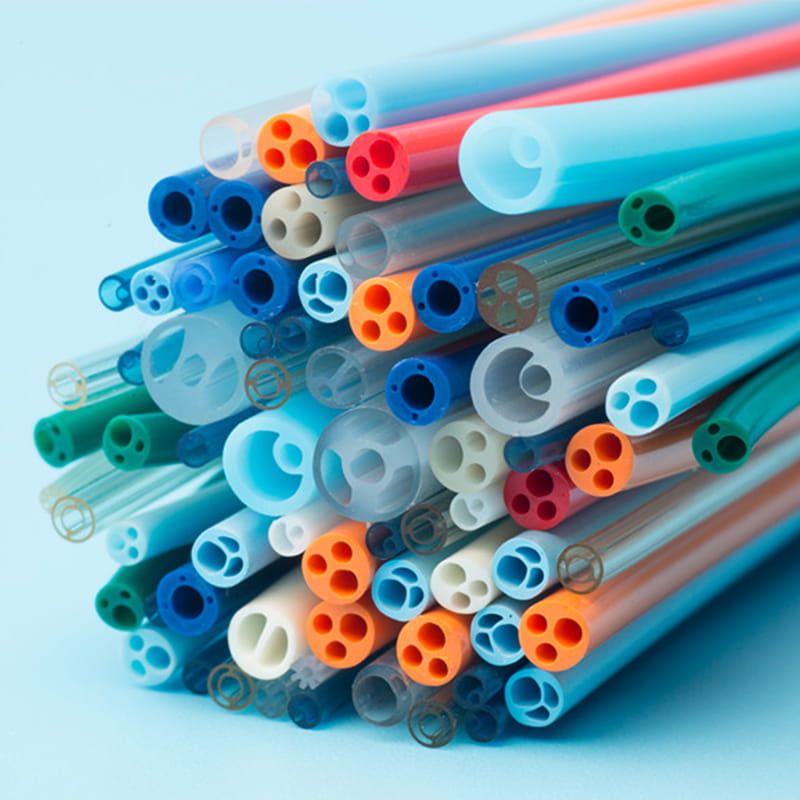

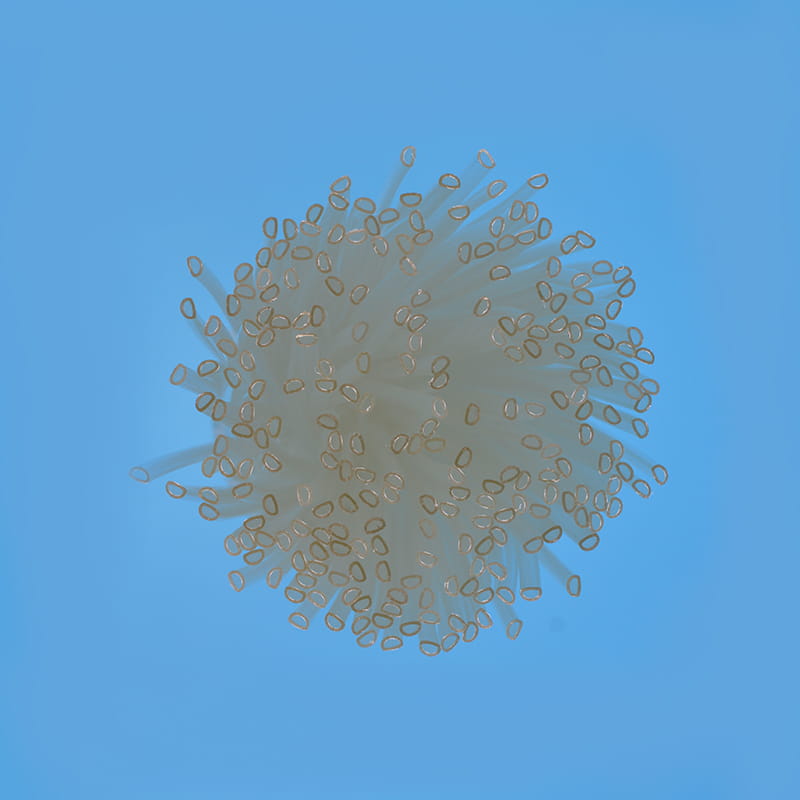

In the medical field, precision catheters are an indispensable tool in many medical operations. These catheters usually need to be in direct contact with the inside of the human body, such as blood vessels, lumens, etc., so their material selection is particularly critical. Common materials such as polytetrafluoroethylene (PTFE), nylon, and polyetheretherketone (PEEK) are widely used in the manufacturing of medical precision catheters due to their excellent biocompatibility and in vivo stability.

1. Polytetrafluoroethylene (PTFE)

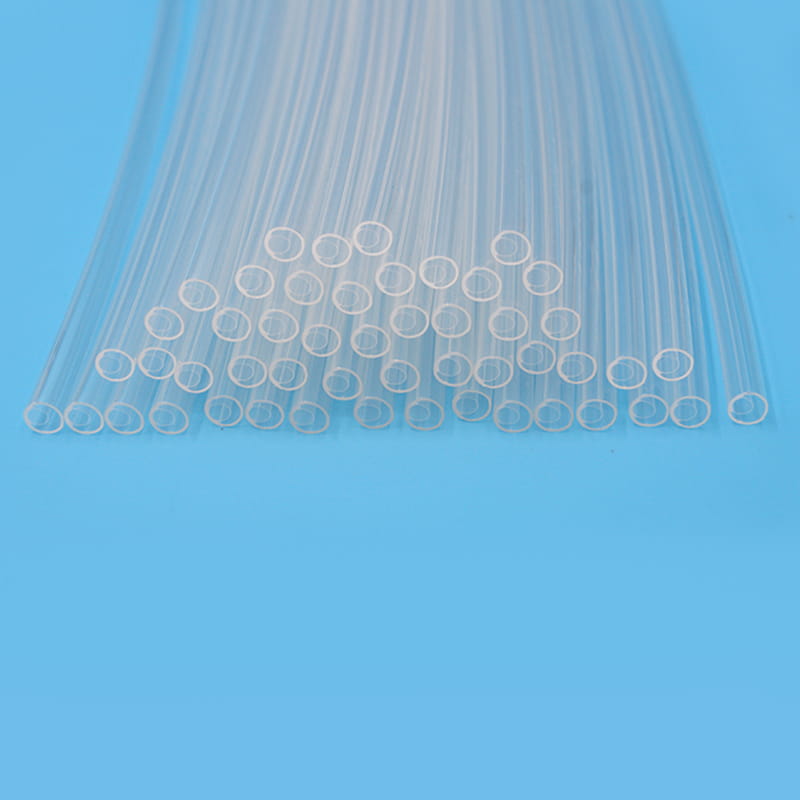

Polytetrafluoroethylene (PTFE) is a polymer material known for its excellent chemical stability, thermal stability and electrical insulation. In the medical field, PTFE is often used to manufacture various catheters, such as vascular catheters, urinary tract catheters, etc. Its excellent biocompatibility allows PTFE catheters to be used safely in the body for a long time without causing inflammatory reactions or immune rejection. In addition, PTFE also has a low friction coefficient, which can reduce the resistance of the catheter during insertion and withdrawal, reducing patient pain.

2. Nylon

Nylon is a synthetic fiber material widely used in the medical field for its high strength, abrasion resistance and corrosion resistance. In the manufacturing of medical precision catheters, nylon materials are usually used to manufacture catheters with certain hardness and support, such as cardiac catheters, imaging catheters, etc. Nylon materials also have good biocompatibility and can be used safely in the body for a long time. In addition, nylon conduits also have high temperature resistance and corrosion resistance, and can maintain stable performance in a variety of complex environments.

3. Polyetheretherketone (PEEK)

Polyetheretherketone (PEEK) is a high-performance thermoplastic that is favored in the medical field for its excellent mechanical properties, chemical stability and biocompatibility. Catheters made of PEEK material have high strength and toughness and can maintain stable performance during complex surgical operations. At the same time, PEEK material also has good biocompatibility and low friction coefficient, which can reduce the inflammatory reaction and friction damage of catheters in the body.

4. The Importance of Material Selection

The material selection of medical precision catheters has an important impact on patient safety and therapeutic efficacy. First, good biocompatibility is the key to ensuring long-term safe use of catheters in the body. If the catheter material causes an allergic reaction or immune rejection in the patient, it will have a serious impact on the patient's health. Secondly, the catheter material should have high stability in the body to ensure that it will not break or deform during the operation. In addition, the physical properties of the catheter material should also meet the needs of surgical operations, such as hardness, toughness, temperature resistance, etc.

Material selection for medical precision catheters is an important step in ensuring patient safety and therapeutic effects. Common materials such as polytetrafluoroethylene (PTFE), nylon, and polyetheretherketone (PEEK) are widely used in the manufacturing of medical precision catheters due to their excellent biocompatibility and in vivo stability. When selecting catheter materials, the patient's specific situation and surgical needs should be fully considered to ensure that the most appropriate material is selected.

For more information, please call us at +86-18913710126 or email us at [email protected].

The medical industry is increasingly relying on advanced materials for various applications, and one...

A medical balloon catheter is a sophisticated medical device designed to perform a variety of proced...

Introduction The TPU Reducer Tube (Thermoplastic Polyurethane Reducer Tube) is a versatile and high-...

In modern medicine, medical catheters are indispensable tools used in a wide range of treatments and...

In the healthcare industry, the importance of selecting the right materials for medical devices cann...

In the era of precision medicine, a small tube often carries the weight of life-saving responsibilit...