Strategies for achieving fluid tightness of medical catheter hubs

1. Material selection: Laying the foundation for sealing

The material selection of medical catheter hubs is the first step to ensure their fluid tightness. The ideal interface material must have good elasticity and be able to deform appropriately when under pressure to adapt to the slight unevenness of the connection surface, thereby effectively preventing fluid leakage. At the same time, corrosion resistance is also an indispensable characteristic, because medical catheters may come into contact with various disinfectants, drugs and even patient body fluids during use, all of which may corrode the material and affect the sealing effect.

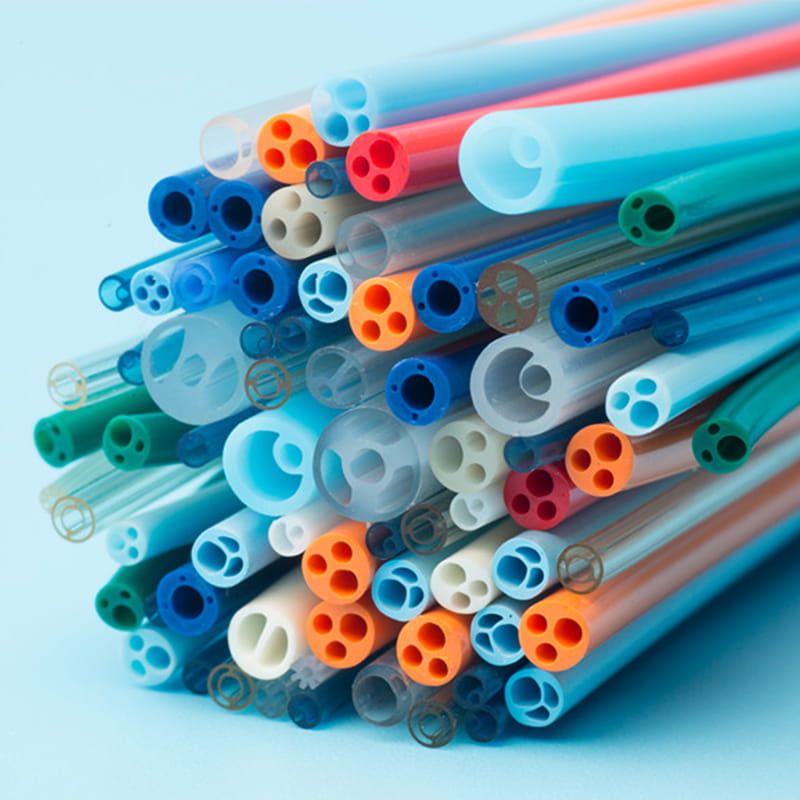

Medical-grade silicone has become one of the commonly used materials for medical catheter hubs due to its excellent biocompatibility, aging resistance and elasticity. It can not only maintain sealing performance for a long time, but also reduce irritation to patient tissues. In addition, thermoplastic elastomers (TPE) have gradually become popular due to their processing flexibility and good elastic recovery ability, especially in situations where complex shapes and customized designs are required. The selection of these materials must strictly follow medical industry standards to ensure safety and effectiveness.

2. Structural design: Optimizing connection and sealing

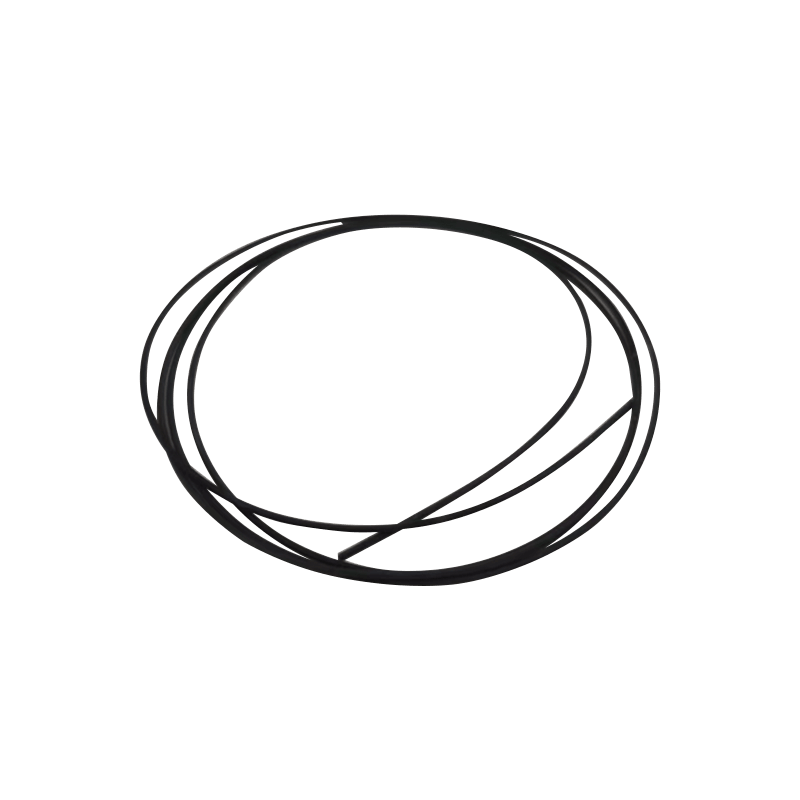

Structural design is another key link in improving the sealing of medical catheter hubs. Reasonable structural design should not only facilitate the operation of medical staff, achieve fast and accurate connection and disconnection, but also ensure that a good sealing state can be maintained under various conditions of use. Multi-layer sealing ring design is a common and effective strategy. By setting multiple layers of sealing rings of different materials or shapes inside the interface, the sealing path can be effectively increased and the reliability and durability of the seal can be improved.

In addition, the standardization of the shape and size of the interface is equally important. This not only helps the compatibility and interchangeability between catheters of different brands and models, and reduces the risk of sealing failure due to mismatch, but also promotes the versatility of medical equipment and reduces hospital operating costs. Therefore, international and domestic standard organizations continue to introduce and improve relevant standards to guide the design and production of medical catheter hubs.

3. Manufacturing process: the last link to ensure sealing quality

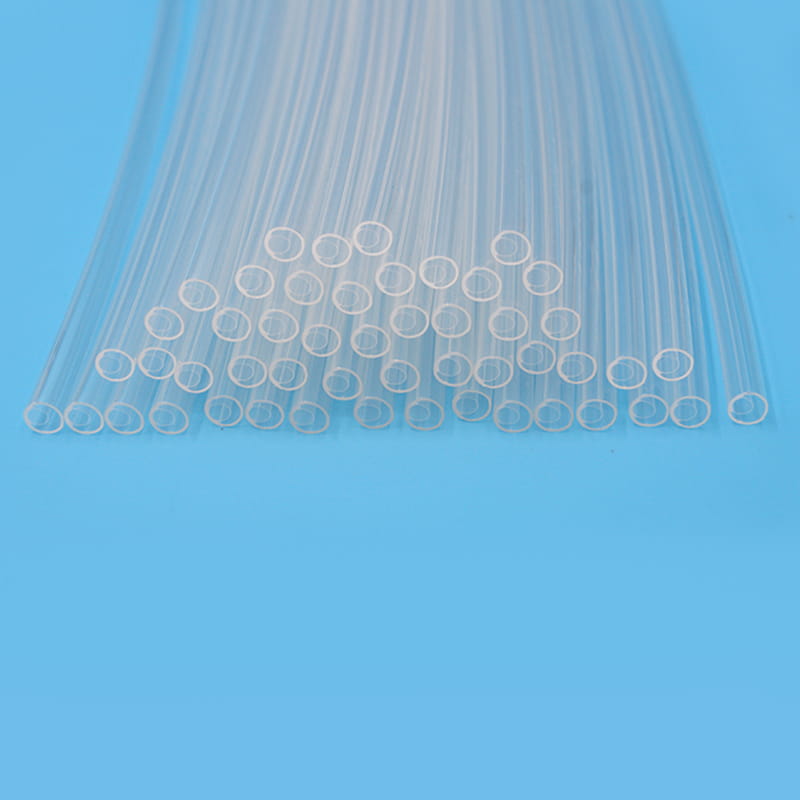

The quality of the manufacturing process is directly related to the final sealing performance of the medical catheter hub. High-quality manufacturing processes can ensure that the dimensional accuracy of the interface reaches the micron level, which is essential for achieving close fit and effective sealing. In addition, the control of surface finish is also a factor that cannot be ignored. A smooth and defect-free surface can reduce the possibility of fluid leakage and extend the service life of the interface.

To achieve this goal, modern manufacturing technologies such as precision injection molding, laser cutting and ultrasonic welding are widely used in the production of medical catheter hubs. These technologies can not only improve production efficiency and consistency, but also meet the strict requirements for material properties and sealing. At the same time, strict quality control processes, including raw material inspection, process monitoring and finished product testing, are also important measures to ensure that each batch of catheter interfaces can meet the predetermined sealing standards.

For more information, please call us at +86-18913710126 or email us at [email protected].

In the era of precision medicine, a small tube often carries the weight of life-saving responsibilit...

In modern healthcare, precise fluid management is crucial for patient safety and treatment efficacy....

Introduction The field of minimally invasive medical procedures has witnessed remarkable growth over...

Introduction The evolution of modern medicine has been significantly shaped by the advent of minimal...

Introduction In the evolving field of minimally invasive treatment, the medical balloon catheter pla...

Introduction to Flexible Medical Tubing What is Flexible Medical Tubing? Flexible medical tubing, of...