How is the precision of Medical Precision Catheter Sheath ensured?

In the medical field, especially in interventional treatments and diagnostics, precision introducer sheaths play a vital role. This type of equipment not only requires a high degree of precision to ensure safety during surgery or treatment, but also maintains stable performance in complex and ever-changing medical environments.

1. Material selection and manufacturing process

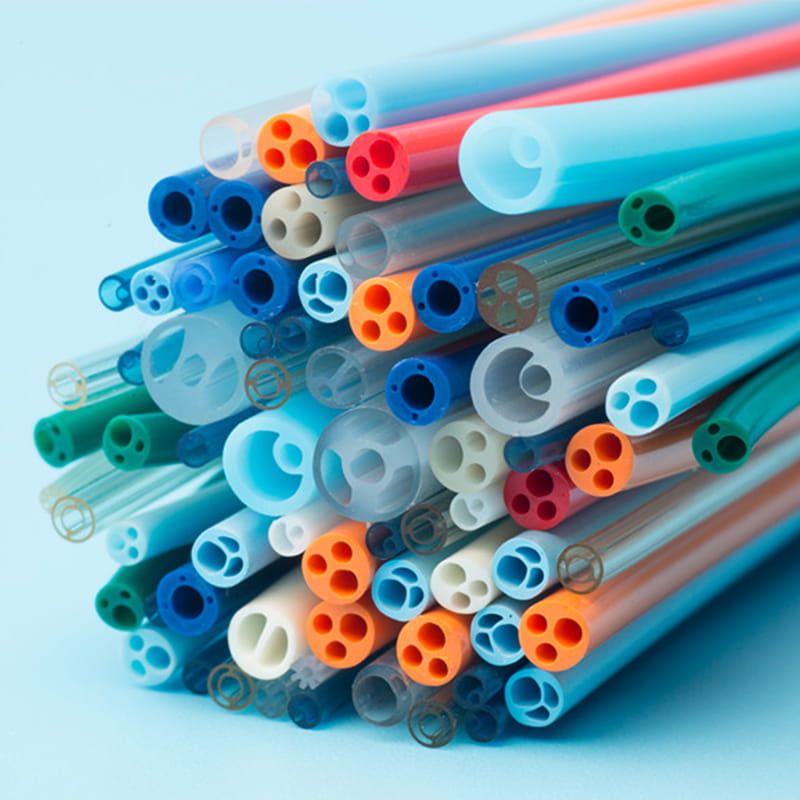

The precision of precision catheter sheaths first stems from its high-quality material selection and exquisite manufacturing process. Usually, these catheter sheaths are made of high-quality materials such as medical stainless steel and polymers. These materials not only have good biocompatibility, but also ensure stable performance under multiple uses or long-term operations.

In terms of manufacturing process, precision catheter sheaths undergo multiple processes of fine processing, including precision cutting, polishing, heat treatment, etc., to ensure their dimensional accuracy and surface finish. In addition, advanced automation equipment and precision measurement tools are used in the manufacturing process to further improve production efficiency and product quality.

2. Design and structural optimization

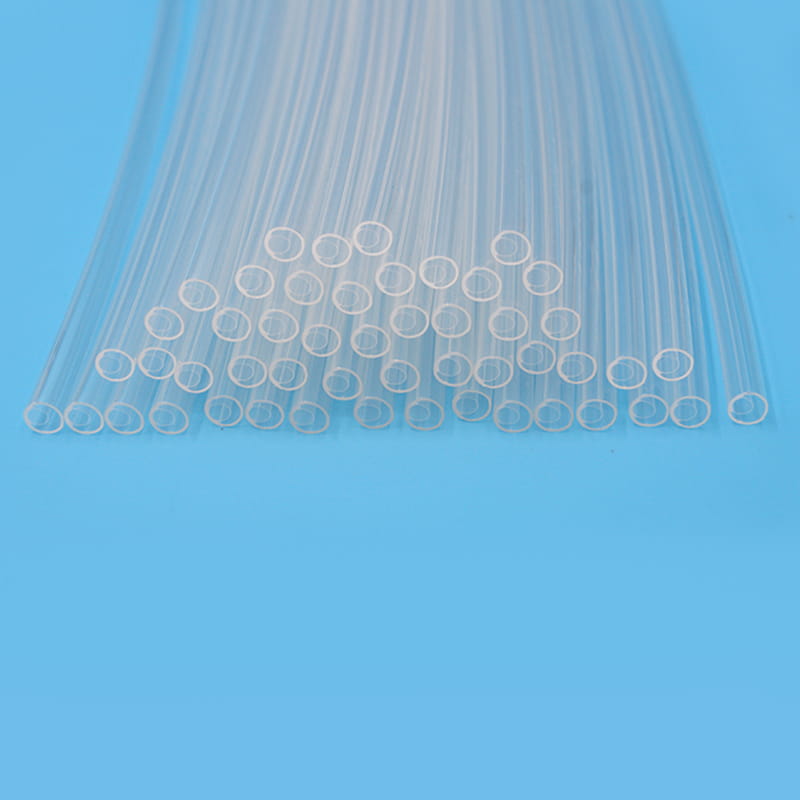

The design of the precision introducer sheath is also key to ensuring its precision. The wall thickness of the introducer sheath is an important factor affecting its performance. An excessively thin wall thickness may cause the catheter sheath to be easily damaged during use, while an excessively thick wall thickness may affect its compliance and passability. Therefore, engineers will accurately calculate and set the appropriate wall thickness based on clinical needs and usage environment. The inner and outer diameter dimensions of the introducer sheath also need to be precisely designed according to clinical needs. The size of the inner diameter directly affects the flow and passability of the catheter, while the outer diameter is related to the space occupied and irritation degree of the catheter sheath in the blood vessel. Engineers will take these factors into consideration to design an introducer sheath that meets clinical needs and has good performance. The head and tail of the introducer sheath are its key structural parts. The design of the head needs to take into account the guidance and smoothness of entering the blood vessel, while the tail needs to take into account the fixation and sealing with the connecting tube. Engineers will improve the operability and safety of the introducer sheath by optimizing the structure of the head and tail.

3. Quality inspection and control

In order to ensure the precision of precision introducer sheaths, manufacturers will conduct strict quality testing and control. These tests include dimensional measurement, material performance testing, biocompatibility evaluation and other aspects.

In terms of dimensional measurement, manufacturers will use precision measuring instruments to test each dimension of the catheter sheath one by one to ensure that it meets the design requirements. In terms of material performance testing, key properties such as tensile strength and corrosion resistance of the catheter sheath will be tested to ensure that it can maintain stable performance during use.

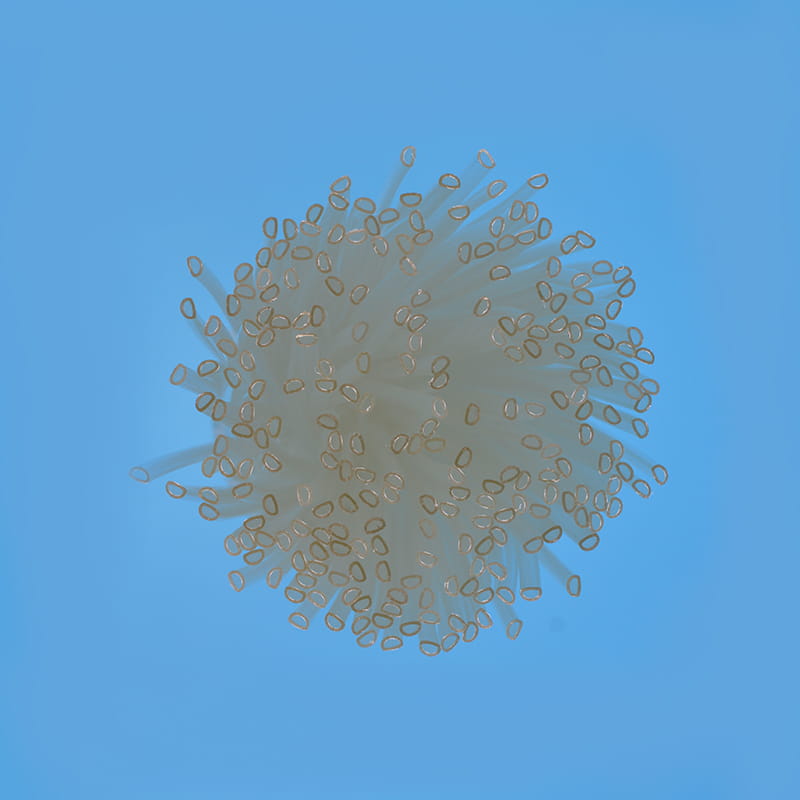

Biocompatibility evaluation is also a very important link. Manufacturers perform biocompatibility testing of the introducer sheath to ensure that it will not cause allergic reactions or other adverse reactions in patients.

4. Use and maintenance

In addition to quality control during the manufacturing process, the use and maintenance of precision catheter sheaths are also important aspects to ensure their precision. During use, medical staff need to strictly follow the operating procedures to avoid excessive bending or twisting of the catheter sheath, which may cause damage or decrease in performance.

In terms of maintenance, the introducer sheath needs to be cleaned and disinfected regularly to remove harmful substances such as dirt and bacteria on the surface. At the same time, care must be taken to avoid collision or friction with other medical devices or equipment during use, so as not to damage the surface or internal structure of the catheter sheath.

For more information, please call us at +86-18913710126 or email us at [email protected].

The medical industry is increasingly relying on advanced materials for various applications, and one...

A medical balloon catheter is a sophisticated medical device designed to perform a variety of proced...

Introduction The TPU Reducer Tube (Thermoplastic Polyurethane Reducer Tube) is a versatile and high-...

In modern medicine, medical catheters are indispensable tools used in a wide range of treatments and...

In the healthcare industry, the importance of selecting the right materials for medical devices cann...

In the era of precision medicine, a small tube often carries the weight of life-saving responsibilit...