In medical catheter curvature control, how to ensure the flexibility and durability of the catheter?

In medical catheter curvature control, how to ensure the flexibility and durability of the catheter?

1.Selection of catheter materials

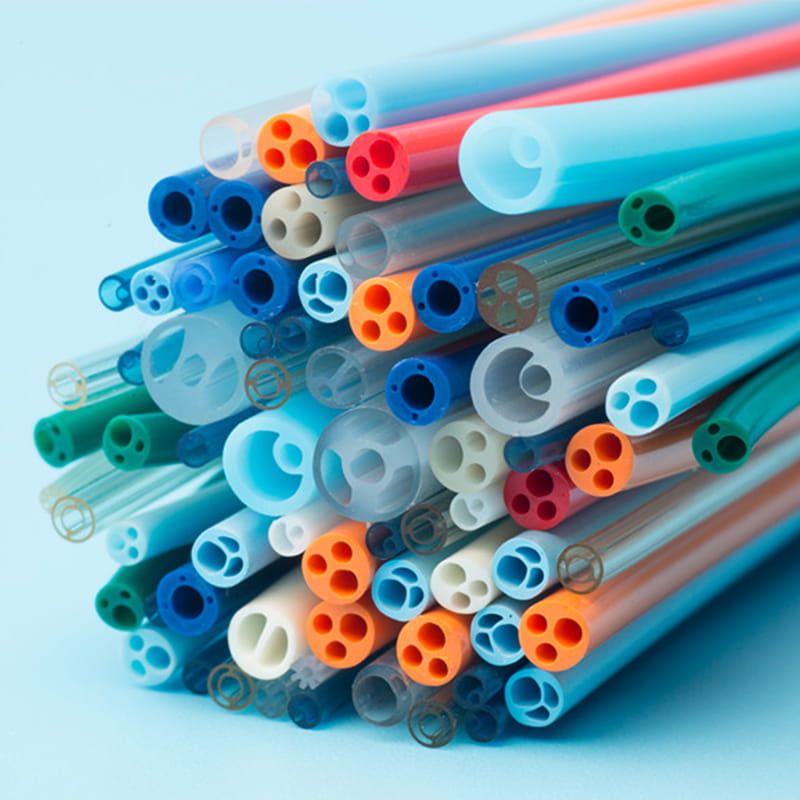

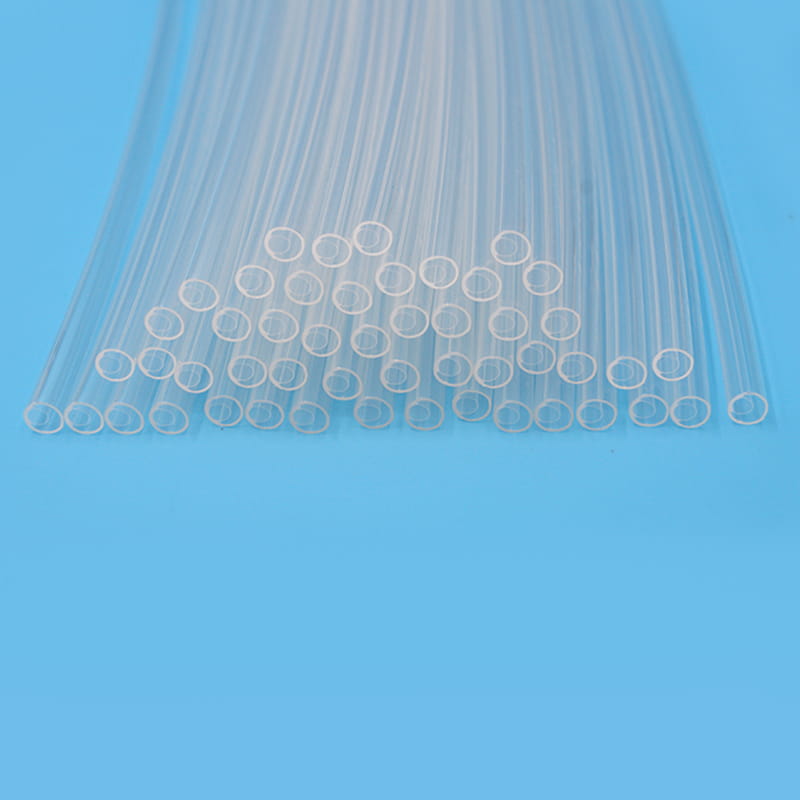

The choice of conduit material is fundamental to ensuring its flexibility and durability. Modern medical catheters are mostly made of polymer materials, such as polytetrafluoroethylene (PTFE), polyurethane (PU), etc. These materials have excellent biocompatibility, chemical stability and mechanical properties and can meet the requirements for use of medical catheters in complex environments. When selecting materials, it is necessary to consider the elastic modulus, elongation at break and other mechanical properties of the material to ensure that the conduit has sufficient flexibility and tensile strength.

2. Optimal design of duct structure

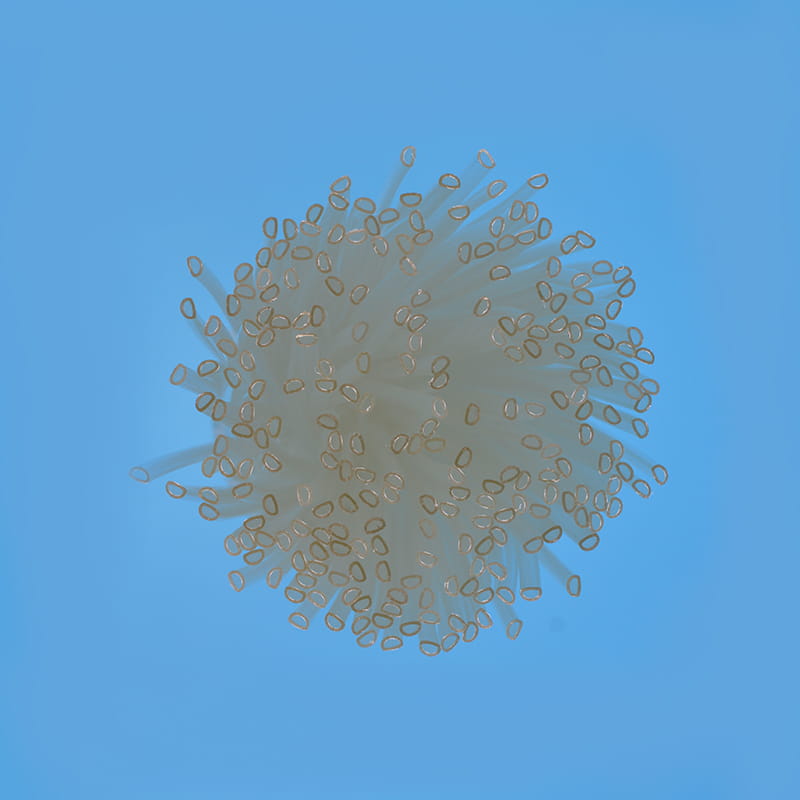

Select the appropriate material based on the application scenario and required performance of the catheter. For example, for conduits that require a high degree of flexibility, you can choose materials with a lower elastic modulus; for conduits that require high durability, you can choose materials that are wear-resistant and corrosion-resistant. Consider the biocompatibility of materials, especially in medical applications, to avoid adverse reactions to patients. The structural design of the conduit should take into account its expected bending radius, wall thickness, length and other parameters. These parameters will directly affect the flexibility and durability of the catheter. Multi-layer composite structures, corrugated structures, etc. can be used to improve the pushing performance, flexibility, strength and other characteristics of the catheter. Multi-layer composite structures can achieve specific performance requirements through a combination of different materials; corrugated structures can adjust the bending performance and strength of the conduit by changing the shape and size of the corrugations. The catheter can be designed with a support structure inside to increase its pressure resistance and stability. At the same time, reasonable internal structure design can also reduce the resistance of fluid in the conduit and improve the efficiency of fluid transmission.

3. Application of curvature control technology

Curvature control technology is an important means of ensuring catheter flexibility and durability. By precisely controlling the curvature of the catheter, the catheter can travel more flexibly in complex human environments and reduce damage to patient tissue. Currently, commonly used curvature control technologies include thermoforming, mechanical bending, and laser processing. These technologies can adjust the curvature and shape of the catheter as needed to meet different treatment needs.

4. Catheter durability test

Conduit durability testing is an important step in ensuring that the conduit can maintain excellent performance in actual use. During the test process, the conduit needs to be tested for wear resistance, pressure resistance, tensile resistance and other performance tests. These tests simulate the stresses the conduit would experience in actual use to evaluate its durability and reliability. Through testing, problems with the catheter can be discovered in time and improvements can be made to improve the service life and safety of the catheter.

5. Duct air tightness test

The air tightness test of the conduit is a key link to ensure that gas leakage will not occur during the use of the conduit. During the test, it is necessary to conduct a sealing test on the inside and outside of the conduit to prevent gas or other liquids from penetrating into the conduit and affecting the normal use of the conduit. Through air tightness testing, it can be ensured that the conduit can maintain stable performance under extreme conditions such as high pressure and high flow rate.

6. Quality control and continuous improvement

In medical catheter curvature control, quality control and continuous improvement are important guarantees to ensure catheter flexibility and durability. By establishing a strict quality control system, the catheter manufacturing process can be comprehensively monitored and managed to ensure that each link meets relevant standards and requirements. At the same time, by collecting and analyzing user feedback, product quality data and other information, potential problems can be discovered and solved in a timely manner, and the design and production of catheters can be continuously improved and optimized.

For more information, please call us at +86-18913710126 or email us at [email protected].

A medical balloon catheter is a sophisticated medical device designed to perform a variety of proced...

Introduction The TPU Reducer Tube (Thermoplastic Polyurethane Reducer Tube) is a versatile and high-...

In modern medicine, medical catheters are indispensable tools used in a wide range of treatments and...

In the healthcare industry, the importance of selecting the right materials for medical devices cann...

In the era of precision medicine, a small tube often carries the weight of life-saving responsibilit...

In modern healthcare, precise fluid management is crucial for patient safety and treatment efficacy....